关注微信

关注微信

400-885-8508

400-885-8508

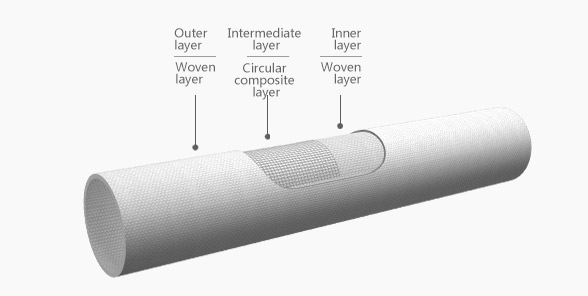

BWFRP power and communication pipelines are made of high performance fiber composites and epoxy resin. They are composed of braided layer, middle layer and outer layer. They are interlaced by high performance fiber longitudinal and transverse braiding and extrusion. It has the characteristics of high ring stiffness, high tensile strength, high and low temperature resistance, high electrical insulation, superior thermal conductivity, corrosion resistance/water resistance, flame retardant, safety and environmental protection, light pipe and so on. Products with incomparable advantages of traditional pipes, by the majority of customers and the market favor!

①High ring-stiffness

③Strong tensile resistance

⑤Smooth inner walls

⑦Excellent thermal conductivity property

⑨Corrosion and water resistance

②High-low temperature resistance

④High electric insulating property

⑥Strong flame resistance

⑧Easy transportation and installation

⑩Safe and Environmental-friendly

| Specifications(mm) | Size(mm)/d | Size(mm)/t | Weight(kg/m) | Ring-stiffness grade(kpa) | Measured results(kpa) |

|---|---|---|---|---|---|

| Communication pipes | |||||

| BWFRP100x2.0x6000 | 100 | 2.0 | 1.3 | 8.0 | 10 |

BWFRP100x3.0x6000

| 通信管道 | |||

|---|---|---|---|

| Tested items | Standard value | Test method | |

| Appearance | The conduit has even color; there is no crack on inner and outer surface, separated layers, pin holes, impurities, glue shortage area, bubbles and other defects; the inner and outer surfaces should be smooth and flat and should not have sags and crests. Two end surfaces of the conduits should flat without sharp edge and burrs. | Eyeballing | |

Size | Inner diameter(unitmm) | 99.5-100.5 | Inspected with calipers |

| Thickness(unitmm) | 1.9 - 2.1 | ||

| Tensile strength(unitMpa) | ≥200 | DL/T802.2--2017 | |

Tensile strength after immersed in water (unitMpa) | ≥105 | DL/T802.2--2017 | |

Barcol hardness | ≥38 | GB/T3854-2005 | |

| Ring-stiffness (5%) (unitMpa) | ≥8 | GB/T3854-2005 | |

| Load distortion temperature(Tfel.8)℃ | ≥160 | GB/T1634.2-2004 | |

Drop-hammer impact | The pipe wall structure should have no obvious separated layer, fissure or cracking. | DL/T802.2--2017 | |

Joint sealing performance | Maintain 15 minutes under 0.1Mpa water pressure. The joint should not seep and leak water | DL/T802.2--2017 | |

The flattening load retention rate after immersed in water % | ≥85 | GB/T5352-2005 | |

The content of alkali metal oxide % | ≤0.8 | GB/T1549-2008 | |

| Oxygen index % | ≥26 | GB/T8924-2005 | |